Dry ice manufacturing

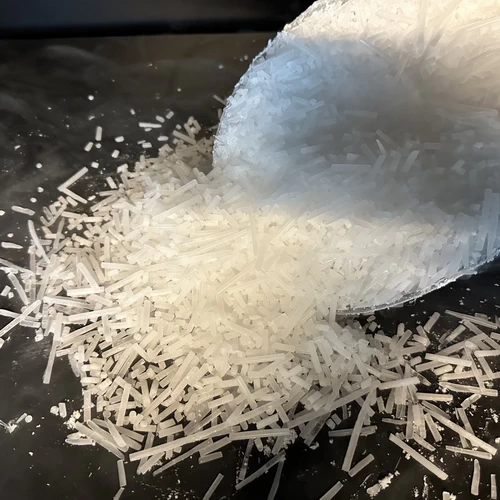

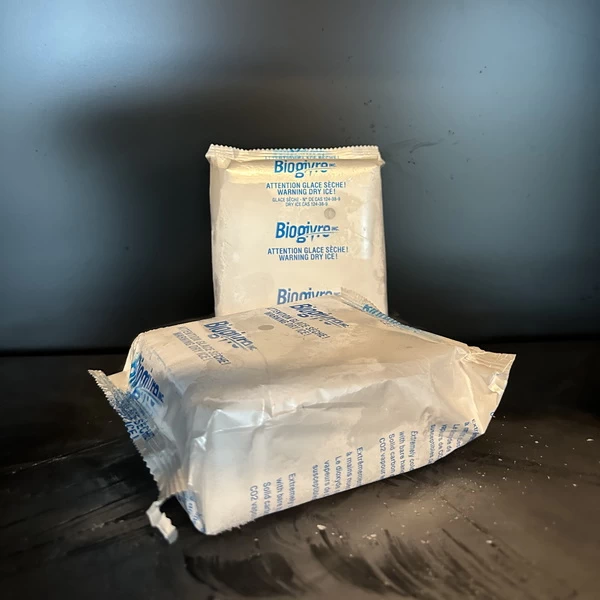

Our dry ice is available in several formats:

3mm

16mm

4"x5"x1"

4"x5"x2"

8 blocks of 4"x5"x3"

Dry ice for hair caps, cooling for cancer treatments

Reduced and unified price per kilo for chemotherapy patients

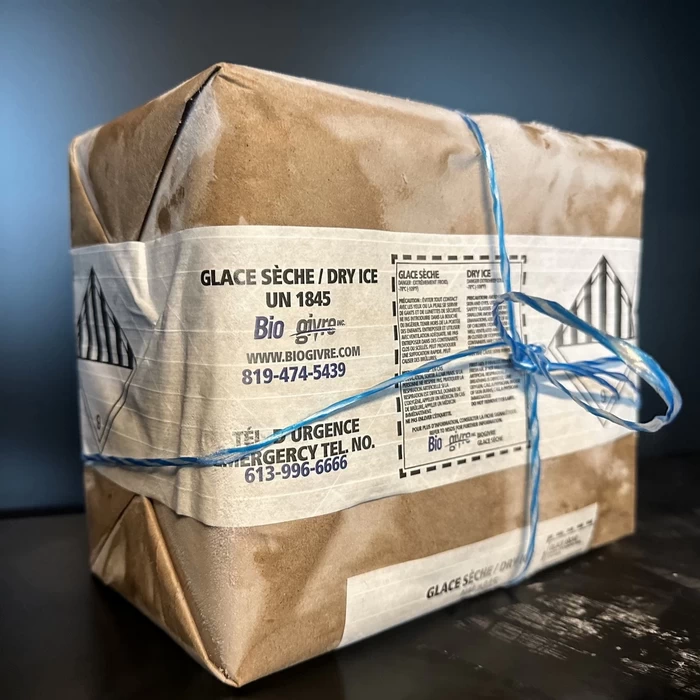

Biogivre is a leading dry ice supplier in Quebec. The company is well aware and sensitive to the cause and is knowledgeable about the use of cooling helmets.

Biogivre works with people undergoing chemotherapy to offer preferential pricing and specifically tailored procedures for customers requiring dry ice for their treatments.

Call: 1 (819) 474-5439

Specify the subject of your order (for cooling helmets) to benefit from a reduced price.

The rate will be automatically applied, and you can pay at your convenience, discussed over the phone.

Pickup or delivery will be arranged with the customer.

Thanks to Biogivre’s collaboration, the preferred price is $2.20 per kilo, mention code 45439

The dry ice can be picked up directly at Biogivre in Drummondville or delivered when possible (delivery fees to be determined).

It is important to order a minimum of 55 lb (25 kilos) of dry ice, Biogivre will be able to guide you for the appropriate format.

Depending on the opening hours of the Biogivre service point and the time of your treatment, it may be easier to pick up the ice the day before. Orders must sometimes be placed the day before collection.

Dry ice (solid CO₂) cannot be stored indefinitely, as it transforms directly from a solid to a gaseous state (sublimation) at -78.5°C. However, there are methods to slow this sublimation and safely preserve it for as long as possible:

Storage Methods

Storage Methods

Use an insulated cooler (Styrofoam/thick polystyrene)

This is the most effective solution for home use.

The thicker the wall and the more tightly sealed (but not airtight) the cooler, the longer the dry ice will last.

Storage in a cool, shaded place

Keep the cooler in a cool, dry, and well-ventilated place (garage, basement, unheated room).

Avoid hot locations or direct sunlight, as this accelerates sublimation.

Limit openings

Each time you open the cooler, warm ambient air enters and accelerates sublimation.

Only remove dry ice when ready to use.

Use large blocks rather than pellets.

Compact blocks last longer than small pellets because they have less surface area exposed to the air.

Important precautions

Important precautions

Do not store in a home freezer:

Dry ice is too cold and can damage the thermostat, cause components to freeze, and CO₂ can accumulate.Ventilation required:

The released CO₂ can displace oxygen in an enclosed space and pose a risk of asphyxiation.Do not seal tightly:

A completely sealed cooler or container can explode under gas pressure.